Hollow Tube Making Machine

Price 50000 INR/ Piece

Hollow Tube Making Machine Specification

- Machine Type

- Tube Mill Machine

- Noise Level

- 70 dB

- Cooling System

- Water Cooling System

- Power Rating

- 15 kW

- Features

- High precision, Durable, Low maintenance

- Drive

- AC Variable Frequency Drive (VFD)

- Motor Power

- 15 HP

- Model No

- HTMM-550X

- Plastic Processed

- PVC, HDPE, LDPE, Metal

- Connectivity Options

- Touch Screen HMI, Ethernet

- Control System

- PLC

- Frame Type

- Heavy Duty Frame

- Lubricating System

- Centralized Automatic Lubrication

- Accuracy

- 0.1 mm

- Frequency

- 50 Hz

- Operating Temperature

- 5C - 40C

- Voltage

- 380V

- Production Capacity

- 45 m/min

- WorkingSpeed

- Up to 50 m/min

- Product Type

- Hollow Tube Making Machine

- Technology

- Advanced PLC Control

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 15 kW

- Pressure

- 120 bar

- Surface Treatment

- Polished

- Dimension (L*W*H)

- 5500 mm x 1200 mm x 1400 mm

- Weight (kg)

- 4000 kg

- Color

- Blue & Silver

- Usage & Applications

- Manufacturing hollow metal/plastic tubes for construction and industrial purposes

Hollow Tube Making Machine Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1-2 Week

- Main Domestic Market

- All India

About Hollow Tube Making Machine

This is a Motorized model precision hollow tube forming machine equipped with 0.5 HP/single phase D.C. motor drive with speed control system. It is designed to give speeds from 0 to 100 RPM supplied with 250mm long tube winding roll (mandrel). It is supplied with one set of drawing die & winding roll (mandrel) for the same. Hollow tube forming dies in various shapes & sizes are available.

Advanced Precision Engineering

Equipped with 12 roll stations and hardened alloy steel rollers, the Hollow Tube Making Machine ensures consistently accurate tube production within a diameter range of 12 mm to 76 mm. Its PLC system delivers fine control and repeatability while maintaining 0.1 mm accuracy, enhancing the quality required by demanding industrial applications.

User-Friendly Operation and Fast Changeover

Designed for operator convenience, this machine features a touch screen display, quick manual or automatic tooling adjustments, and a swift 25-minute changeover time. The electric control cabinet and modern HMI connectivity allow for easy interface and monitoring, ensuring smooth, efficient production workflows.

Robust Construction and Integrated Safety

Manufactured with high-quality mild steel and a heavy-duty frame, the machine guarantees long-term durability. Safety is paramount, with built-in features such as emergency stop, overload protection, and precise temperature controls, making it suitable for intensive use in varied environments.

FAQs of Hollow Tube Making Machine:

Q: How does the automatic flying saw cutter function during tube production?

A: The automatic flying saw cutter enables continuous cutting of tubes to precise lengths without halting tube production. It synchronizes with tube movement, ensuring clean, accurate cuts at operating speeds up to 45 meters per minute.Q: What materials can be processed with this hollow tube making machine?

A: This machine processes a range of materials, including carbon steel, stainless steel, and plastics like PVC, HDPE, and LDPE. Its construction and advanced control systems make it suitable for both metal and plastic tube manufacturing.Q: When is manual versus automatic tooling adjustment recommended?

A: Manual adjustments are ideal for fine-tuning specific parameters or handling unique materials. Automatic adjustments, managed via the PLC and touch screen panel, are best for frequent size changes or high-volume production, enabling rapid and consistent changeovers.Q: Where is this machine best installed for optimal performance?

A: Optimal installation is in a workshop or factory environment with adequate space (dimensions: 5500 x 1200 x 1400 mm) and stable operating temperature (5C40C). Properly leveled floors and VFD-compatible power sources ensure safety and efficiency.Q: What are the benefits of integrating the machine with a high-speed decoiler and welder?

A: Inline integration with a high-speed decoiler and welder streamlines production, reduces material handling, and minimizes downtime. This results in a seamless workflow and greater production efficiency, particularly for large-scale tube manufacturing.Q: How does the machine maintain high accuracy and low maintenance needs?

A: High-precision alloy steel rollers, advanced PLC control, and a centralized automatic lubrication system work together to ensure consistent accuracy (0.1 mm) and minimize maintenance. The polished surface and robust components further contribute to durability and ease of operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Machines Products Category

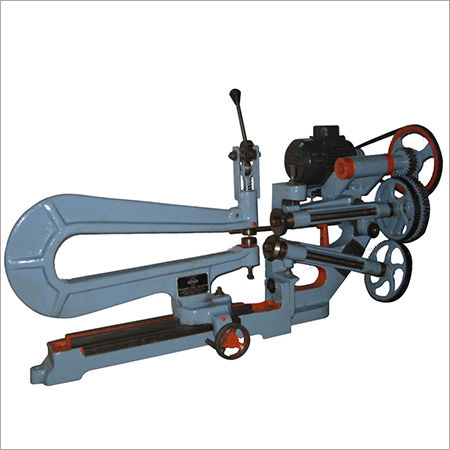

Hydraulic Control Hacksaw Machine

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 220440 Volt (v)

Technology : CNC

Surface Treatment : Other

Operating Type : Automatic

Circle Cutting Machine

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power : 220440 Volt (v)

Technology : CNC

Surface Treatment : Painted

Operating Type : Automatic

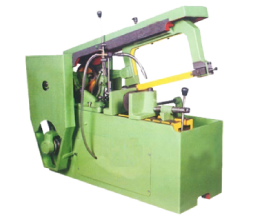

Hydraulic Hacksaw Machine

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 220440 Volt (v)

Technology : CNC

Surface Treatment : Painted

Operating Type : Automatic

Precision Shaping Machine

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 220440 Volt (v)

Technology : CNC

Surface Treatment : Painted

Operating Type : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS