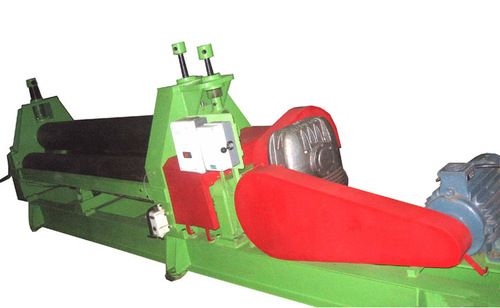

Plate bending Machine

Price 50000 INR/ Piece

Plate bending Machine Specification

- Cooling System

- None (Manual)

- Lubricating System

- Manual Grease Points

- Production Capacity

- up to 10 sheets/hour (depends on operator)

- Drive

- Manual

- Machine Type

- Bench/Workshop Type Plate Bender

- Motor Power

- No Motor (Manual)

- Model No

- PBM-1220

- Accuracy

- 0.5 mm

- Operating Temperature

- Ambient

- Features

- Robust construction, Easy to operate, Low maintenance

- Noise Level

- Low

- Control System

- Manual Lever Control

- Frame Type

- Heavy Duty Welded Frame

- Product Type

- Plate Bending Machine

- Technology

- Mechanical

- Power Source

- Manual

- Operating Type

- Hand Operated

- Power

- N/A (Manual)

- Pressure

- Manual Operation

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- 1500 x 600 x 1100 mm

- Weight (kg)

- Approx. 600 kg

- Color

- Blue & White

- Usage & Applications

- Bending metal plates in workshop and fabrication

Plate bending Machine Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1-2 Week

- Main Domestic Market

- All India

About Plate bending Machine

his is our heavy duty three roll pyramid type power operated plate bending machine in model TPH having capacity to bend 2500 x 25 mm in mild steel. The machine weighs about 6700 kgs and is equipped with 30 HP motor, siemens make on/off starter and reverse/forward switch complete with lubricaton system.

Some of the salient features of our three roll pyramid type plate bending machines are as under:

- This is a fully hydraulic heavy duty shearing machine. Few of its salient features are as under:

- Heavy duty steel fabricated housing amply proportioned to withstand maximum strain.

- Rollers are of forged EN-8 material and run in collar type gun metal bushes.

- Base is of heavy duty girders.

- Centralized lubrication system

- Drive through a series of hob cut properly hardened steel gears and worm reduction gear box.

- Screw jack is provided to keep the top roll in horizontal position when trunion is retracted to facilitate removal of formed shells.

Precision Bending with Manual Control

The PBM-1220 combines mechanical simplicity with precise manual control, allowing operators to achieve 0.5 mm accuracy. Its lever-and-gear operation ensures consistent bending results, while the alloy steel rollers offer durability over extended production runs.

Built for Durability and Ease of Use

This machine features a heavy duty welded frame and corrosion-resistant paint for longevity and reliability. A blue and white finish gives it a professional appearance, and its ergonomic design means setup and operation require minimal effort from the user.

Workshop-Ready and Versatile Applications

Ideal for small and medium workshops, the PBM-1220 handles up to 10 sheets per hour, depending on operator proficiency. Suitable for bending metal plates in fabrication settings, it comes partially assembled for easy installation and includes all necessary accessories.

FAQs of Plate bending Machine:

Q: How is the PBM-1220 Plate Bending Machine operated?

A: The PBM-1220 is operated manually using a lever and gear system, enabling users to bend metal plates accurately without the need for electric power or motors.Q: What types of materials can be processed with this machine?

A: This plate bender is designed for mild steel sheets up to 3 mm in thickness and 1220 mm in length, making it suitable for standard workshop and fabrication needs.Q: What is included with the machine upon delivery?

A: The machine is shipped partially assembled and includes standard handles and adjustment tools to facilitate setup and maintenance.Q: Where can the PBM-1220 Plate Bending Machine be installed?

A: It is floor mountable, making it ideal for bench or workshop environments where stability and fixed positioning are required for effective plate bending.Q: What benefits does the corrosion-resistant paint finish provide?

A: The corrosion-resistant paint finish ensures long-term durability by protecting the machine from rust and environmental wear, maintaining its appearance and performance.Q: What is the expected production capacity of the machine?

A: Depending on operator proficiency, the PBM-1220 can bend up to 10 sheets per hour, with consistent precision due to its manual control system.Q: How is maintenance performed on this plate bending machine?

A: Maintenance is low and straightforward, with manual grease points provided for lubrication of moving parts, and no complex electrical or cooling systems to service.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Machines Products Category

Multifunction Woodworking Machine

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Green

Warranty : 01 year

Power Source : Electricity

Technology : CNC

Corrugated Fastener Machine

Price 700000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Warranty : 01 year

Power Source : Electricity

Technology : CNC

Hand Operated Shearing Machine

Minimum Order Quantity : 1 Piece

Color : Green and black

Warranty : 01 year

Power Source : Electricity

Technology : CNC

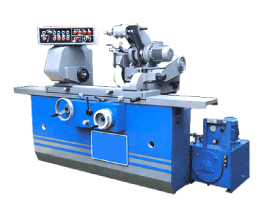

Precision Cylindrical Grinder

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Color : Blue

Warranty : Yes

Power Source : Electricity

Technology : CNC

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS